Services

contact on us:

We offer a versatile range of highly portable Nondestructive (NDT/NDE) services to ASME Sec V, ASTM, API, BS EN ISO and Client requirements, with very rapid post-inspection reporting, in the following methods:

✔ Magnetic Particle Testing (MPI) – versatile fluorescent MT solutions at height, on ground, and in explosive environments ensures a high probability (PoD) of crack detection, if present on the part. Affordable visible MT solutions are also available for small or large volume of parts.

✔ Liquid Penetrant Testing (LPT) – vast range of highly effective consumables, both fluorescent and visible, ensures your PT needs for virtually all non-magnetic parts can be readily met.

✔ Visual Inspection (VT) – drilling tools ID borescope, precise pit depth gauging and full dimensional measurements to various standards.

✔ High Precision dimension measurements or verification using OD micrometers, ID micrometers (tubular and 3-point contact mics), Dial bore gauging of tools for precise ID verification or ovality issues either due to machining / manufacturing errors or in-service wear.

✔ Conventional Ultrasonic Testing or Flaw Detection (UT) on welds, forgings, some castings and rolled products.

✔ Advanced Ultrasonic Flaw Detection such as Phased Array UT (PAUT) and Time of Flight Diffraction (ToFD) UT – Currently being developed for future deployment.

✔ Through-coating Ultrasonic Thickness Gauging or Measurement (UTG/UTM) on OCTG, Tank shells, and many similar applications – no need to waste time with classical paint removal.

✔ Electromagnetic Testing (ET) – Eddy Current Testing (ECT) for magnetic and non-magnetic components, coated or uncoated.

✔ Our ultra-portable and very precise ECT weld inspection system guarantees the fastest personnel deployment to handle all your in-service and fabrication stage welding inspection needs.

✔ Magnetic Flux Leakage (MFL) testing or dual-function EMI for OCTG products such as drill pipes, casing and tubing.

✔ CSWIP 3.1 Weld Inspections to ISO 17637

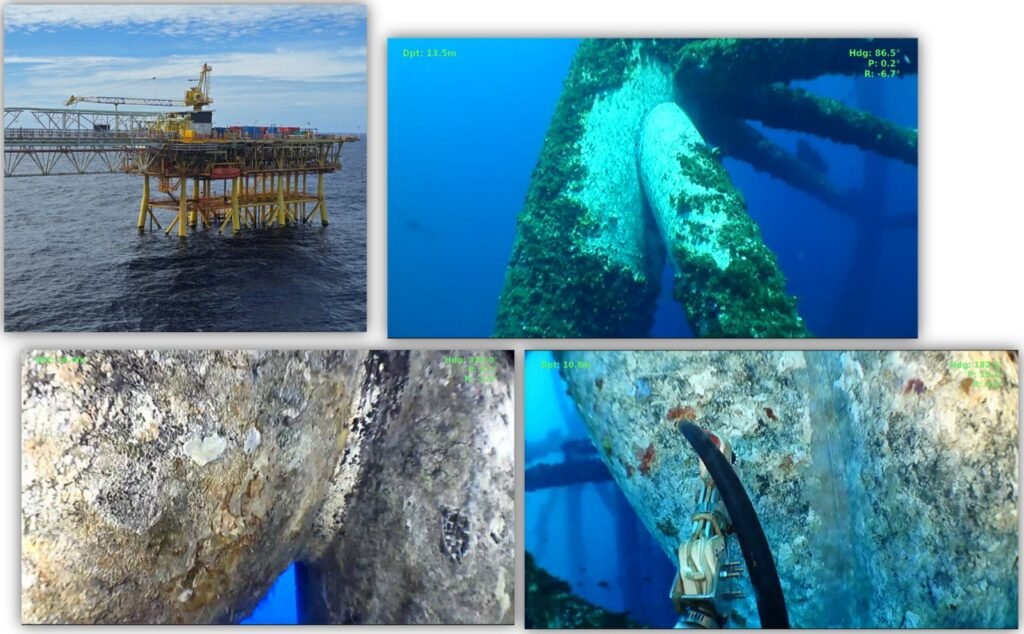

✔ Underwater Inspection of Lieu of Drydocking (UWILD) using Eddy Current Testing (ECT)

✔ Do you require an expert Underwater Eddy Current (UWEC) inspection consultant for your offshore UWILD needs? PRS offers very experienced independently certified NDT level III personnel with a proven field track record for various Jack-up rig sizes in a wide range of offshore operating environments. We help direct both the ROV crew and the requesting client on the most efficient and effective approach to get the job done with direct onsite reporting prior to inspection crew dispatch from the rig.

✔ Working with our ultra-portable mini-ROV Partners in South East Asia, all your UWILD needs – Thorough cleaning of underwater weld nodes/joints (T-K-Y), GVI, CVI, UWEC – can be swiftly and reliably taken care of.

✔ We are a phone call or an email away from promptly attending to your UWILD needs at the most competitive industry rates.

PRS offers Oil and Gas clients affordable inspection consultancy services to DS-1 and various common API standards for the following equipment categories:

✔ Bottom Hole Assembly (BHA) Inspection to DS-1 Vol 3

✔ Drill Pipe Inspection to DS-1 Vol. 3

✔ Hevi-Wate Drill Pipe (HWDP) Inspection to DS-1 Vol. 3

✔ Specialty tools NDT to DS-1 Vol. 4

✔ Tubing & Casing Inspection to API RP 5A5 & B1

✔ CRA Pipe Inspection, Tally and Handling Management

✔ Hoisting & Handling Equipment Inspection to API RP 7L & 8B

✔ Masts & Substructures and Derricks, including full rig shutdown inspection services to API RP 4G and 54

✔ 3rd Party QA/QC Inspection

✔ Bespoke Inspections to Client Requirements

We offer onshore drilling rig clients with cost-effective full rig shutdown / decommissioning inspections to API RP 4G / client requirements. Kindly contact us for the relevant pre-job negotiations. We hope you’ll be impressed by our service delivery efficiency and affordability, God willing.

We provide our Onshore and offshore drilling industry clients with:

✔ DROPS inspection services.

✔ Rope Access level 1, 2 and 3 NDT services

✔ Kindly reach out to us for very affordable day rates.

Our experienced independent ASNT NDT III staff can affordably service inspection training needs in the following categories:

✔ NDT Level I & II Trainings in MPI, LPT, VT, UT, ECT

✔ General technical NDT Level III Consultancy Services including failure analysis, particularly for Oil and Gas drilling tools.

✔ Drill Stem Tools, Handling Tools, OCTG Inspection, Training & Consultancy Services to DS-1 and various API standards

✔ DROPS Training Services

✔ Lifting Equipment Training Services

✔ Lifting Equipment Operational Planning Services

PRS offers affordable inspection consultancy services for lifting appliances and accessories in the following aspects:

✔ Design and implementation of full-fledged lifting inspection operations to ISO 17020 requirements.

✔ Provision of hands-on technical training for already certified inspectors who may be facing actual job implementation limitations due to insufficient practical knowledge for particular types of equipment. You just provide the facility and an experienced, fully certified lifting inspection expert will attend to your technical needs.

✔ Classroom training of certified or uncertified lifting inspection personnel aiming to augment their overall technical knowledge and/or attend certification exams.

✔ Design or develop inspection forms, procedures or guides

✔ Review, update and/or validate lifting inspection legislation or standards registers

✔ Advise clients about the purchase of suitable or relevant inspection equipment and/or tools for various field applications

PRS offers consultancy services for lifting operations in the following areas:

✔ Lifting operations planning and consultancy services for heavy lifts up to 1000 tonnes.

Using efficiently designed Method Statement forms, we can help clients to develop effective and safe Lift Plan(s) for their lifting operations across several industries including Oil & Gas, Heavy Metal Fabrication or Manufacturing plants, Ship Building / Fabrication Yards, Aviation Industry, Fabrication Yards for concrete and cement-based products.

✔ Lifting Gear Rentals

✔ Test Weight Rentals

✔ Load sensing or Dynamometer equipment rentals up to 100 tonnes capacity

PRS offers the following services:

✔ CSWIP 3.1 Welding inspection services to ISO 17637

✔ NDT of non-autogenous & autogenous fusion welds – MMA/SMAW, TIG/TGW, GMAW (MIG/MAG), SAW/SW, plasma, electron beam, laser or oxy-fuel gas welded joints.

✔ Welding Procedure preparation, verification and qualification to BS EN ISO 15614‑1 & ASME Section IX:2019

✔ General welding inspection consultancy services.

✔ Very versatile Hardness Testing (HT), both Leeb (D-type) and UCI (10N to 50N) methods, across a substantial hardness testing range from thin to thick metallic sections as well as for very small to large parts. Parts can be testing either in the installed/assembled or disassembled condition in any direction or orientation.

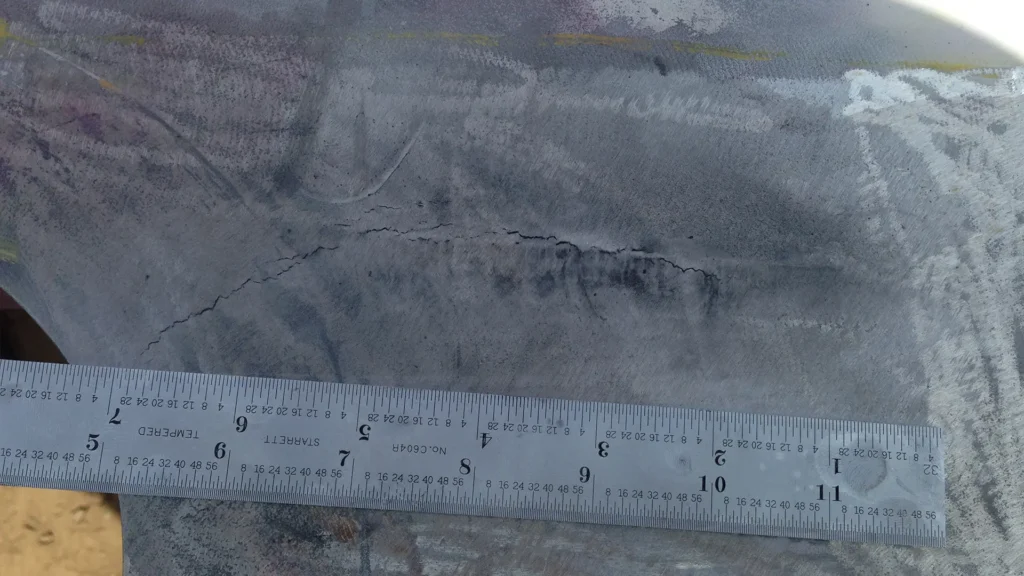

– Types of Failures

– Failure Frequency

– Probable Cause(s)

– Data Collection & Input

✔ The many types of down hole failures that occur to drilling tool components can sometimes be the result of the inspection company’s lack of foresight in providing information on the tools service capabilities and life expectancy as fatigue sets in and machined tolerances begin to wear.

✔ Although specifications are used to determine a tool’s acceptance or rejection criteria, this does not always suffice because a perfectly acceptable tool to prevailing criteria could also be in a ‘borderline’ condition which would greatly increase upside risks regarding the tool’s continued serviceability.

✔ PRS is experienced in the collection and analysis of information on potential borderline tools to ensure risky tools are not returned to drilling service.

✔ More importantly, PRS NDT Level III technical personnel can analyse historical damage data of rejected tools and determine root cause(s) which may be used to recommend customized inspections on the same or associated equipment.

✔ Further investigation can be done to determine the root cause(s) of the failure and also determine the failure stage – premature or otherwise. In many cases this may help detect other tools in a similar condition before they too approach the point of failure.

✔ To eliminate the cause of any particular failure, the probable cause(s) must first be determined and then preventive action can be taken to reduce its frequency, if not completely eliminate it. It’s all about treating the cause and not the symptoms.

Our ancillary technical consultancy services include:

✔ Technical Audit services to ISO 17020 standard

✔ 3rd Party QMS Audit Services to ISO 9001:2015

✔ Product & Process audits to relevant API, BS, EN, ISO, ASTM, ASME inspection standards & bespoke customer requirements